CNC woodworking machines have significantly transformed the woodworking industry in Australia. These machines utilise computer numerical control (CNC) technology to automate various woodworking tasks, leading to enhanced precision and efficiency. They cater to a wide range of applications, from small-scale custom projects to large-scale manufacturing. CNC Woodworking Machines Australia enable complex designs to be realised with minimal manual intervention, streamlining production processes. As a result, they have become an essential tool for many Australian woodworkers, helping them achieve consistent and high-quality outputs. The adoption of CNC technology reflects the industry's shift towards more advanced and automated solutions, contributing to its ongoing evolution.

The Rise of CNC Woodworking Machines

The adoption of CNC woodworking machines in Australia has surged due to the rising demand for precision and efficiency in the industry. These machines have revolutionised traditional woodworking methods by enabling automated cutting, carving, and shaping processes. The integration of CNC technology allows for seamless translation of complex designs into tangible products, bridging the gap between creative concepts and practical execution.

This technological advancement has not only increased productivity but has also set new standards for accuracy and quality. As a result, many Australian woodworkers have embraced CNC machines to meet the evolving needs of both small-scale custom projects and large-scale manufacturing.

Advantages of CNC Machines in Woodworking

CNC woodworking machines offer unparalleled precision and consistency, crucial for high-quality craftsmanship. They enable complex and intricate designs to be executed with remarkable accuracy, which significantly reduces material waste. The automation of cutting and shaping processes minimises human error, leading to uniformity in production. This consistent output streamlines operations, allowing woodworking businesses to meet tight deadlines efficiently.

Additionally, the reduction in manual labour not only enhances productivity but also allows skilled craftsmen to focus on more creative and value-added tasks. The ability to replicate exact designs repeatedly ensures that even large-scale projects maintain the same high standard throughout production.

Applications of CNC Woodworking Machines

CNC woodworking machines are utilised across a broad spectrum of the Australian woodworking industry. These machines are integral in creating bespoke furniture, producing cabinetry, and fabricating intricate wood art. In small workshops, CNC technology facilitates the production of custom pieces, allowing artisans to achieve detailed craftsmanship that would be time-consuming with traditional methods. Larger manufacturers benefit from the capability to mass-produce items with high precision, ensuring consistency and quality across large volumes.

Additionally, CNC machines are employed in specialised sectors such as architectural woodwork, where precise and complex components are required. This versatility makes CNC woodworking machines invaluable tools, catering to both custom and large-scale production needs within the industry.

CNC Machine Technology and Features

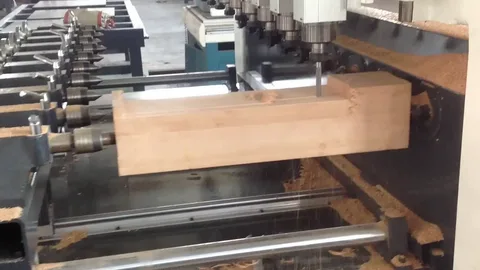

CNC woodworking machines boast sophisticated technology that enhances their functionality and versatility in the industry. These machines are equipped with high-precision cutting tools and robust motor systems, ensuring detailed and accurate execution of designs. Advanced control software allows operators to input intricate design specifications, which the machine then executes with remarkable accuracy. The integration of real-time monitoring systems ensures consistent performance, while adaptive features enable adjustments based on material type and project requirements.

Additionally, these machines often come with automated tool-changing capabilities, reducing downtime and increasing efficiency. The use of touchscreens and intuitive interfaces simplifies the programming process, making it easier for operators to manage complex projects. The technological features of CNC woodworking machines continue to evolve, pushing the boundaries of what can be achieved in the woodworking industry.

Challenges in Implementing CNC Technology

The integration of CNC technology into woodworking shops in Australia presents several challenges. Initial investment costs for CNC woodworking machines can be prohibitive, especially for smaller businesses. Additionally, the shift from traditional methods to CNC technology requires a significant learning curve, as operators must be trained to handle advanced software and machinery.

The complexity of these machines also means that regular maintenance and technical support are crucial to ensure uninterrupted operation. Furthermore, space constraints within existing workshops can pose logistical issues when accommodating these larger, sophisticated machines. Despite these obstacles, the long-term benefits of CNC technology often justify the initial challenges faced during implementation.

The Future of CNC Woodworking in Australia

The future of CNC woodworking in Australia appears bright, with ongoing advancements promising even greater innovation. Emerging technologies such as artificial intelligence and machine learning are poised to further enhance the capabilities of CNC machines, enabling more sophisticated and customised designs. The trend towards increased automation is expected to continue, potentially reducing the need for manual intervention and allowing for more complex projects to be completed with ease.

Additionally, developments in software integration will likely make CNC technology more accessible to a broader range of users, including smaller workshops. As these advancements unfold, the woodworking industry in Australia is set to benefit from improved efficiency, precision, and creative potential.

Environmental Impact of CNC Woodworking

CNC woodworking machines promote sustainable practices in the industry by optimising material usage and reducing waste. Enhanced precision means fewer mistakes, thus conserving resources. The automation of tasks ensures consistent results, leading to more efficient production cycles. This efficiency translates into lower energy consumption as projects are completed more quickly and with fewer errors.

Additionally, the precise cutting and shaping capabilities of CNC machines often mean less need for rework, further conserving resources. The move towards eco-friendly materials and the reduction of manual intervention also contribute to a smaller environmental footprint. Overall, the implementation of CNC technology supports a more sustainable and resource-efficient approach to woodworking.

Economic Benefits of CNC Woodworking Machines Australia

The economic benefits associated with CNC Woodworking Machines Australia are extensive, making them a valuable asset for the industry. Their automated precision reduces material waste, translating to significant cost savings. Enhanced productivity and efficiency enable businesses to complete projects faster, increasing overall output. The reduction in manual labour costs allows for better allocation of resources towards other critical areas.

Additionally, the ability to undertake more complex and customised projects opens new revenue streams, diversifying business opportunities. Over time, the improved operational efficiency and expanded capabilities offered by CNC woodworking machines contribute to a stronger financial performance and competitive advantage for businesses within the woodworking industry.

CNC Machines and Customisation Capabilities

CNC technology enables the creation of bespoke designs with remarkable ease. These machines excel in producing intricate patterns and customised pieces that traditional methods would find challenging. The capability to input specific design parameters allows for a high degree of personalisation, catering to individual customer needs and preferences. This adaptability is particularly valuable for artisans and small-scale workshops seeking to offer unique, one-of-a-kind products.

Additionally, the precision of CNC machines ensures that even the most complex custom designs are executed flawlessly, maintaining consistency across multiple pieces. This level of customisation not only broadens the range of products that can be offered but also enhances the overall appeal and value of the woodworking business.

Safety Considerations in CNC Woodworking

Safety in CNC woodworking involves multiple layers of precaution. Comprehensive training is imperative to familiarise operators with machine functions and software interfaces. Safety features such as emergency stop buttons and protective shields are essential to prevent accidents. Regular maintenance checks ensure machines operate correctly and reduce the risk of malfunctions. Proper ventilation systems are necessary to manage dust and fumes generated during the cutting processes.

Additionally, operators should wear appropriate personal protective equipment (PPE) like safety goggles and hearing protection to safeguard against potential hazards. Ensuring the workspace is well-organised and free of obstructions also contributes to a safer working environment. Establishing clear safety protocols and procedures is vital for maintaining a secure and efficient operation in workshops utilising CNC technology.

Integration of CNC Machines in Existing Workshops

Integrating CNC woodworking machines into existing workshops in Australia requires strategic planning to ensure a smooth transition. Workshops may need to undergo spatial adjustments to accommodate the size and operational needs of CNC machines. Infrastructure modifications, such as enhancing power supply and ventilation systems, are essential to support the advanced machinery.

Proper layout design can optimise workflow and ensure that CNC machines are efficiently utilised alongside traditional tools. Additionally, establishing clear operational protocols and training staff on new procedures can mitigate potential disruptions during the integration process. Effective planning and execution can enable workshops to leverage the capabilities of CNC technology, thereby enhancing productivity and output quality.

Training and Skills Development for CNC Operators

Developing the essential skills required to operate CNC woodworking machines is a cornerstone of successful integration within the industry. A comprehensive approach to training ensures that businesses can fully leverage the advanced capabilities of this technology, leading to improved efficiency and quality.

Comprehensive Training Programmes

Effective training programmes must thoroughly cover both the software and hardware aspects of CNC woodworking. This ensures operators achieve proficiency in programming the machines, correctly setting them up for various tasks, and performing routine maintenance to keep them in optimal working condition.

Invaluable Hands-on Experience

Hands-on experience with the actual CNC machines is absolutely invaluable. It allows operators to develop a practical understanding of the technology's nuances, building the confidence and expertise needed to manage diverse woodworking projects effectively and efficiently.

Continuous Professional Development

The woodworking industry, particularly with CNC technology, is constantly evolving. Regular workshops and specialised courses are crucial for keeping staff updated on the latest advancements, fostering a culture of continuous improvement and ensuring skills remain relevant and cutting-edge.

Collaborative Training Solutions

Collaborating with educational institutions and seasoned industry experts can provide woodworking businesses with bespoke training solutions. These partnerships ensure that learning is tailored to specific operational needs, offering practical and theoretical knowledge directly applicable to real-world scenarios.

Enhancing Operational Efficiency

Investing in this focused skills development not only significantly enhances operational efficiency and precision in woodworking but also empowers operators. By mastering CNC capabilities, they can unlock the full potential of the machinery, driving innovation and competitiveness in the industry.

Conclusion

CNC Woodworking Machines Australia have profoundly transformed woodworking industry, offering unmatched precision, efficiency, and customisation capabilities. Their adoption streamlines production, reduces waste, and enhances output quality, benefiting both small workshops and large manufacturers. While initial investment and training present challenges, the long-term economic and environmental advantages are substantial. As technology continues to evolve, with advancements like AI integration, CNC woodworking promises an even brighter future, solidifying its role as an indispensable tool for modern Australian woodworkers committed to innovation and high-quality craftsmanship.

Frequently Asked Questions

What are the key advantages of using CNC Woodworking Machines Australia?

CNC Woodworking Machines Australia offer unparalleled precision and consistency, crucial for high-quality craftsmanship, enabling intricate designs with minimal material waste. Their automation reduces human error, ensuring uniformity in production and allowing businesses to meet deadlines efficiently. This also frees skilled craftspeople to focus on more creative, value-added tasks, significantly boosting productivity and maintaining consistent high standards across projects.

What are the primary applications of CNC woodworking machines, and what technological features do they possess?

CNC woodworking machines are used across various applications in Australia, including creating bespoke furniture, cabinetry, intricate wood art, and for mass production in larger manufacturing settings. They feature high-precision cutting tools, robust motor systems, advanced control software for intricate designs, and real-time monitoring. Automated tool-changing capabilities, touchscreens, and intuitive interfaces further enhance their functionality and efficiency.

What challenges might Australian businesses face when implementing CNC technology, and what does the future hold for CNC woodworking in the country?

Implementing CNC technology in Australia can involve significant initial investment costs and a steep learning curve for operators. Regular maintenance and technical support are crucial, and workshops may face space constraints. Despite these challenges, the future of CNC woodworking in Australia is bright, with emerging technologies like AI and machine learning promising enhanced capabilities, increased automation, and greater accessibility for more users.

How do CNC woodworking machines impact the environment and offer economic benefits to Australian businesses?

CNC woodworking machines promote environmental sustainability by optimising material usage and reducing waste through enhanced precision. This efficiency also leads to lower energy consumption. Economically, their automated precision reduces material waste, translating to significant cost savings. Enhanced productivity, reduced manual labour costs, and the ability to undertake complex, custom projects open new revenue streams, strengthening financial performance.

| Related Business Listings |