The construction industry has seen significant technological advancements over the years, and one of the most impactful innovations in the roofing sector is the rise of roofing machines. These specialized machines have transformed how contractors approach roofing projects, allowing for faster installation, greater precision, improved safety, and higher-quality results.

What Are Roofing Machines?

Roofing machines are specialized equipment designed to automate and streamline various aspects of the roofing installation process. Depending on the type of roofing system being installed, different machines are used to form, cut, and fasten roofing materials with incredible precision.

By using roofing machines, contractors can significantly reduce manual labor, minimize human error, and complete projects more efficiently.

Types of Roofing Machines

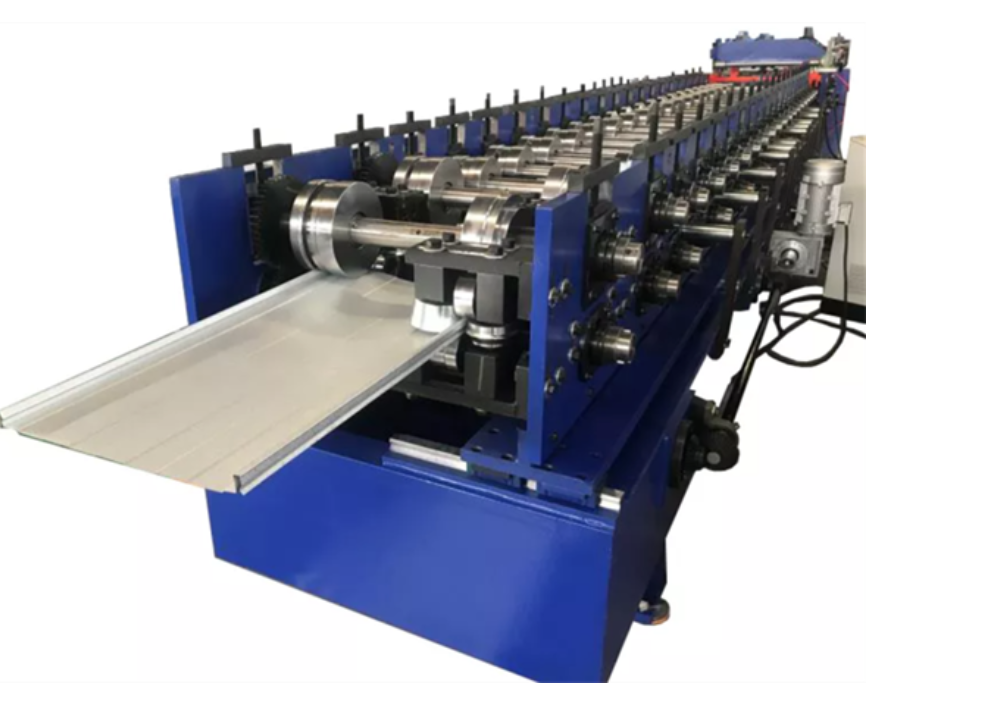

1️⃣ Roll Forming Machines

Roll-forming machines are used to create continuous metal roofing panels directly on the job site. They feed coils of metal through a series of rollers that shape the material into panels with precise dimensions.

- Commonly used for standing seam metal roofs

- Custom lengths minimize waste

- On-site production reduces transportation costs

2️⃣ Seamers

Seamers are essential for standing seam metal roofing systems. These machines crimp or seam the panels together, ensuring a weather-tight seal.

- Automated seaming improves consistency

- Reduces risk of leaks

- Speeds up installation

3️⃣ Membrane Roofing Machines

For flat or low-slope roofs, membrane roofing machines heat-weld or adhere large rolls of roofing membrane (like TPO, PVC, or EPDM) to the roof surface.

- Creates durable, watertight seams

- Increases installation speed

- Reduces risk of adhesive failure

4️⃣ Shingle Cutting Machines

These machines cut asphalt shingles with precision, allowing for more uniform installation and reduced material waste.

- Consistent cuts improve appearance

- Saves time on trimming and fitting

5️⃣ Automatic Fastening Machines

Fastening machines automate the process of securing roofing materials to the structure.

- Ensures consistent fastening patterns

- Improves structural integrity

- Reduces operator fatigue

Benefits of Roofing Machines

✅ Increased Speed and Productivity

By automating many time-consuming tasks, roofing machines enable crews to complete projects much faster than manual methods.

- Shorter project timelines

- Ability to take on more jobs

- Reduced labor costs

✅ Enhanced Precision and Quality

Roofing machines ensure consistent cuts, seams, and fastening, resulting in higher-quality finished products.

- Fewer installation errors

- Improved durability

- Better overall appearance

✅ Reduced Waste and Cost Savings

On-site roll forming allows contractors to produce panels to exact lengths, minimizing scrap material.

- Lower material costs

- Reduced disposal fees

- More efficient use of raw materials

✅ Improved Worker Safety

Many roofing machines eliminate the need for dangerous manual tasks, such as hand-cutting or seaming at great heights.

- Fewer on-site accidents

- Reduced risk of repetitive strain injuries

- Less time spent on hazardous tasks

✅ Flexibility for Custom Projects

Roofing machines make it easy to produce custom panels and components, allowing contractors to meet unique architectural requirements.

- Custom panel lengths and profiles

- Adaptable to complex roof designs

- Easier to accommodate customer requests

Why Roofing Machines Are the Future of Roofing

The roofing industry is becoming increasingly competitive, and roofing machines give contractors a significant edge. Companies that invest in roofing machines benefit from:

- Faster project turnaround times

- Higher customer satisfaction

- Greater profitability

- Reduced labor dependency

As the demand for high-performance roofing systems grows, especially for metal and membrane roofs, roofing machines will continue to play a central role in meeting modern construction needs.

Factors to Consider When Investing in Roofing Machines

While the advantages are clear, contractors should consider a few key factors before purchasing roofing machines:

- Initial Cost: High-quality machines require significant upfront investment.

- Training: Operators must be properly trained to maximize efficiency and minimize errors.

- Maintenance: Regular servicing is essential to keep machines running smoothly.

- Space Requirements: Some machines require adequate space for operation and storage.

Working with reputable manufacturers and investing in employee training will ensure long-term success and maximum return on investment.

The Environmental Impact of Roofing Machines

Roofing machines also contribute to more sustainable construction practices by:

- Minimizing material waste

- Reducing transportation emissions (with on-site fabrication)

- Producing long-lasting roofing systems that require fewer replacements

Sustainable construction is no longer a trend—it’s a necessity. Roofing machines help contractors align with environmentally responsible building practices.

Final Thoughts

Roofing machines have revolutionized the roofing industry by improving speed, precision, safety, and profitability. As technology continues to advance, these machines will only become more efficient and accessible, allowing roofing contractors to deliver better results for their clients while reducing labor costs and environmental impact.