Lithium car batteries have become a game-changer in the automotive sector, mainly due to their remarkable efficiency and longevity. Unlike traditional lead-acid batteries, these advanced power sources offer a higher energy density, translating to longer driving ranges for electric vehicles. The technology behind lithium batteries leverages the movement of lithium ions to generate electrical energy, a process that is both efficient and reliable. With the rise of electric vehicles, the demand for lithium batteries has surged, prompting significant advancements in battery technology. As consumers and manufacturers increasingly prioritise sustainability, lithium-car batteries are at the forefront of this transformation, contributing to a greener future for transportation.

Components and Structure

Lithium-car batteries are composed of several essential parts: the anode, cathode, electrolyte, separator, and current collectors. The anode, often made from graphite, serves as the site where lithium ions are stored during the charging process. The cathode, typically composed of lithium metal oxides, holds the lithium ions when the battery discharges.

The electrolyte, a lithium salt dissolved in a solvent, allows the movement of ions between the anode and cathode. The separator, a porous membrane, keeps the anode and cathode apart, preventing short circuits while allowing ion flow.

Current collectors, usually made of aluminium and copper, channel the electrical energy generated during the ion movement to power the vehicle. These components work in unison to deliver efficient and reliable energy storage, making lithium batteries a cornerstone of modern electric cars.

How Lithium RV Batteries Work

The core operation of lithium RV batteries is centres on the movement of lithium ions between the anode and cathode. During discharge, lithium ions travel from the anode through the electrolyte to the cathode, creating a flow of electrons that generates electrical energy to power the vehicle.

This process is reversed during charging, where lithium ions move back to the anode. The efficiency of this ion movement is facilitated by the electrolyte and the separator, ensuring that the ions can travel freely without causing short circuits.

This cycle of discharging and charging can be repeated many times, thanks to the robust nature of the materials used in lithium-car batteries. The reliability of this ion exchange process underpins the performance of modern electric vehicles, offering both high efficiency and long-lasting power.

Types of Lithium Batteries

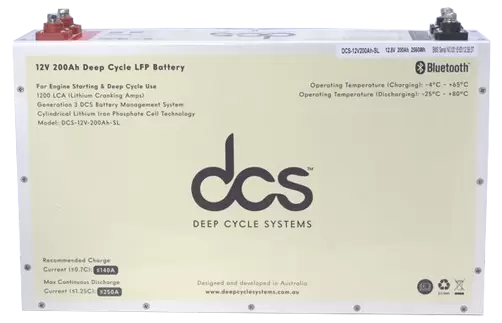

Lithium batteries used in vehicles come in various forms, each suited for specific needs. Lithium Iron Phosphate (LiFePO4) batteries are known for their excellent thermal stability and long cycle life, making them a safe and durable option. Lithium Nickel Manganese Cobalt Oxide (NMC) batteries are favored for their balanced performance, offering a good mix of energy density, lifespan, and safety.

They are widely used in electric vehicles due to their versatility. Lithium Nickel Cobalt Aluminium Oxide (NCA) batteries are distinguished by their high energy density and long lifespan, making them ideal for high-performance electric vehicles.

Each type offers unique benefits, allowing manufacturers to choose the most suitable option based on the specific requirements of the car. By understanding the characteristics of these different types, consumers and manufacturers can make informed decisions to optimise performance and safety.

Benefits of Lithium-car batteries

Lithium-car batteries offer several advantages over traditional options. They are significantly lighter, which improves vehicle efficiency and performance. With a higher energy density, these batteries enable electric cars to achieve longer driving ranges. Additionally, they have a faster charging capability, reducing downtime for drivers.

Lithium-car batteries also have a longer lifespan compared to their lead-acid counterparts, providing better value over time. They perform well in a variety of temperature conditions, making them versatile for different climates. Environmentally, lithium batteries contribute to lower emissions, aiding in the reduction of the overall carbon footprint associated with transportation.

Challenges and Limitations

Lithium-car batteries, despite their advantages, present several challenges. One of the primary issues is the risk of thermal runaway, which can occur if the battery overheats. This can lead to safety concerns and potential damage to the vehicle. Additionally, lithium batteries can underperform in extreme temperature conditions, both hot and cold, which affects their reliability.

Another limitation is the high cost of raw materials such as cobalt and nickel, which impacts the overall cost of battery production. Moreover, the current technology restricts both the capacity and the speed of charging, necessitating further research and development to improve these aspects.

The extraction and processing of lithium also raise environmental and ethical concerns, particularly regarding mining practices and their impact on local communities and ecosystems. These challenges underscore the need for ongoing innovation and enhanced methods to improve the safety, efficiency, and sustainability of lithium-ion car batteries.

Charging and Maintenance

Regular maintenance and proper charging protocols are essential for maximizing the lifespan of lithium-car batteries. It's crucial to use chargers that are specifically designed for your battery type to ensure efficient and safe charging. Avoid letting the battery charge drop to zero, as this can negatively affect its longevity.

It's also beneficial to keep the battery within a moderate temperature range during charging and discharging. Periodically checking the battery for signs of wear or damage can help identify potential issues before they become significant problems.

Additionally, using a Battery Management System (BMS) can help monitor the battery's health and performance, providing real-time data and alerts. Ensuring proper ventilation and avoiding exposure to extreme temperatures can further enhance the battery's efficiency and safety. Following these practices can significantly contribute to the optimal functioning of your lithium car battery.

Safety Considerations

Overheating

Overheating in lithium-car batteries can lead to thermal runaway, posing significant safety risks. Proper ventilation and monitoring systems are crucial to prevent this issue.

Physical Damage

To handle lithium batteries safely, avoid exposing them to high temperatures and physical damage. Always use protective equipment when inspecting or installing batteries. Ensure they are disposed of properly to minimise environmental harm.

Advancements in Lithium RV Battery Technology

Recent strides in lithium battery technology are paving the way for enhanced energy storage solutions. Solid-state batteries are emerging as a promising innovation, offering greater energy density and improved safety by replacing the liquid electrolyte with a solid material. This change reduces the risk of overheating and enhances overall battery stability.

Additionally, researchers are exploring silicon anodes as a replacement for conventional graphite anodes, aiming to significantly boost energy capacity. Fast-changing technologies are also under development, aiming to reduce charging times and improve convenience for electric vehicle users.

Another exciting area of progress is the enhancement of Battery Management Systems (BMS), which are becoming more sophisticated in monitoring and optimizing battery performance. These advancements hold great potential to revolutionize the efficiency and safety of lithium-car batteries.

Impact on the Automotive Industry

The adoption of lithium-car batteries is driving substantial changes in the automotive industry, promoting a shift towards electric vehicles (EVs). This transition is encouraging manufacturers to innovate in areas such as vehicle design, powertrain technology, and energy management systems.

The improved energy density and longevity of lithium batteries are enabling the creation of more efficient and high-performance electric vehicles. Additionally, the automotive industry is investing heavily in research and development to address the challenges associated with lithium batteries, such as thermal management and fast-charging capabilities.

This focus is accelerating advancements in battery technology and infrastructure, including the expansion of charging networks. The shift towards electric vehicles is also impacting supply chains, with a growing emphasis on securing sustainable sources of raw materials, such as lithium, cobalt, and nickel.

As a result, there is a notable push towards more ethical and environmentally friendly environmentally friendly mining practices. The rising demand for electric vehicles is reshaping market dynamics, compelling traditional car manufacturers to diversify their product lines and adopt new technologies. This transformation is not only altering how vehicles are powered but also influencing broader industry standards and regulations aimed at reducing emissions and promoting sustainable practices.

Cost and Economic Factors of Battery Lithium Car

The decreasing cost of battery lithium car has significantly influenced the accessibility of electric vehicles. This price reduction is attributed to advancements in manufacturing processes, increased production scale, and technological improvements. As a result, electric cars are becoming a more viable option for a broader range of consumers.

For manufacturers, the economic implications are profound. Investment in research and development is crucial for further reducing costs and enhancing battery performance. The shift towards lithium batteries is also affecting supply chains, with a growing emphasis on securing stable and ethically sourced raw materials, such as lithium, cobalt, and nickel.

This focus is driving innovation in mining practices and encouraging the adoption of recycling methods to reclaim valuable materials. The economic benefits extend beyond the automotive industry, influencing energy markets and infrastructure development, particularly in the expansion of charging networks. These economic factors are playing a pivotal role in the transition to a more sustainable transportation model, fostering both consumer and industrial shifts towards electric mobility solutions.

Environmental Impact and Recycling

Recycling lithium-car batteries plays a crucial role in mitigating environmental concerns. The recycling process involves retrieving valuable materials, such as lithium, cobalt, and nickel, thereby reducing the need for new mining activities and conserving natural resources.

Despite the advantages, the recycling infrastructure is still underdeveloped in many regions, posing challenges in efficiently managing the growing number of end-of-life batteries. Innovations in recycling techniques are essential to make the process more cost-effective and environmentally friendly.

The environmental impact of improper disposal can be substantial, resulting in soil and water contamination. Therefore, it's vital to establish comprehensive recycling programmers and policies to ensure the responsible handling of used batteries.

Efforts are also being made to design batteries that are easier to disassemble and recycle, further reducing their ecological footprint. Enhanced public awareness and regulatory frameworks will be key in promoting sustainable recycling practices, thus contributing to a more circular economy in the automotive sector.

Conclusion

Lithium car batteries are revolutionizing the automotive sector by enhancing vehicle performance, efficiency, and sustainability. Their lightweight nature and higher energy density allow electric cars to travel greater distances on a single charge, addressing one of the major concerns for electric vehicle adoption. These batteries also offer quicker charging times, which is increasingly vital as the charging infrastructure continues to expand. However, challenges such as thermal management and the ethical sourcing of raw materials remain critical areas for ongoing research and development. Manufacturers are investing in innovative technologies, such as solid-state batteries and enhanced Battery Management Systems (BMS), to address these issues.

FAQ

How long do lithium car batteries last?

On average, lithium car batteries have a lifespan of 8 to 15 years, influenced by factors such as usage patterns and maintenance practices.

Are lithium-car batteries recyclable?

Yes, recycling lithium-car batteries is essential for recovering valuable materials like lithium, cobalt, and nickel, thus reducing the need for new mining activities and conserving resources. Efficient recycling methods are crucial to minimise environmental impact.

What are the main types of lithium batteries used in cars?

The primary types of lithium batteries in automotive applications are Lithium Iron Phosphate (LiFePO4), Lithium Nickel Manganese Cobalt Oxide (NMC), and Lithium Nickel Cobalt Aluminium Oxide (NCA). Each type offers distinct advantages, including improved thermal stability, balanced performance, and high energy density.

| Related Business Listings |