In the competitive world of rice milling, every detail matters. From the quality of raw paddy to the precision of each machine, the outcome depends on a blend of efficiency, innovation, and reliability. Among the key components in this process are rice polishing wheels, which play a crucial role in determining the shine, texture, and overall quality of milled rice. Choosing the right rice polishing wheels manufacturer is not just a matter of procurement—it's a strategic investment in your mill’s performance and reputation.

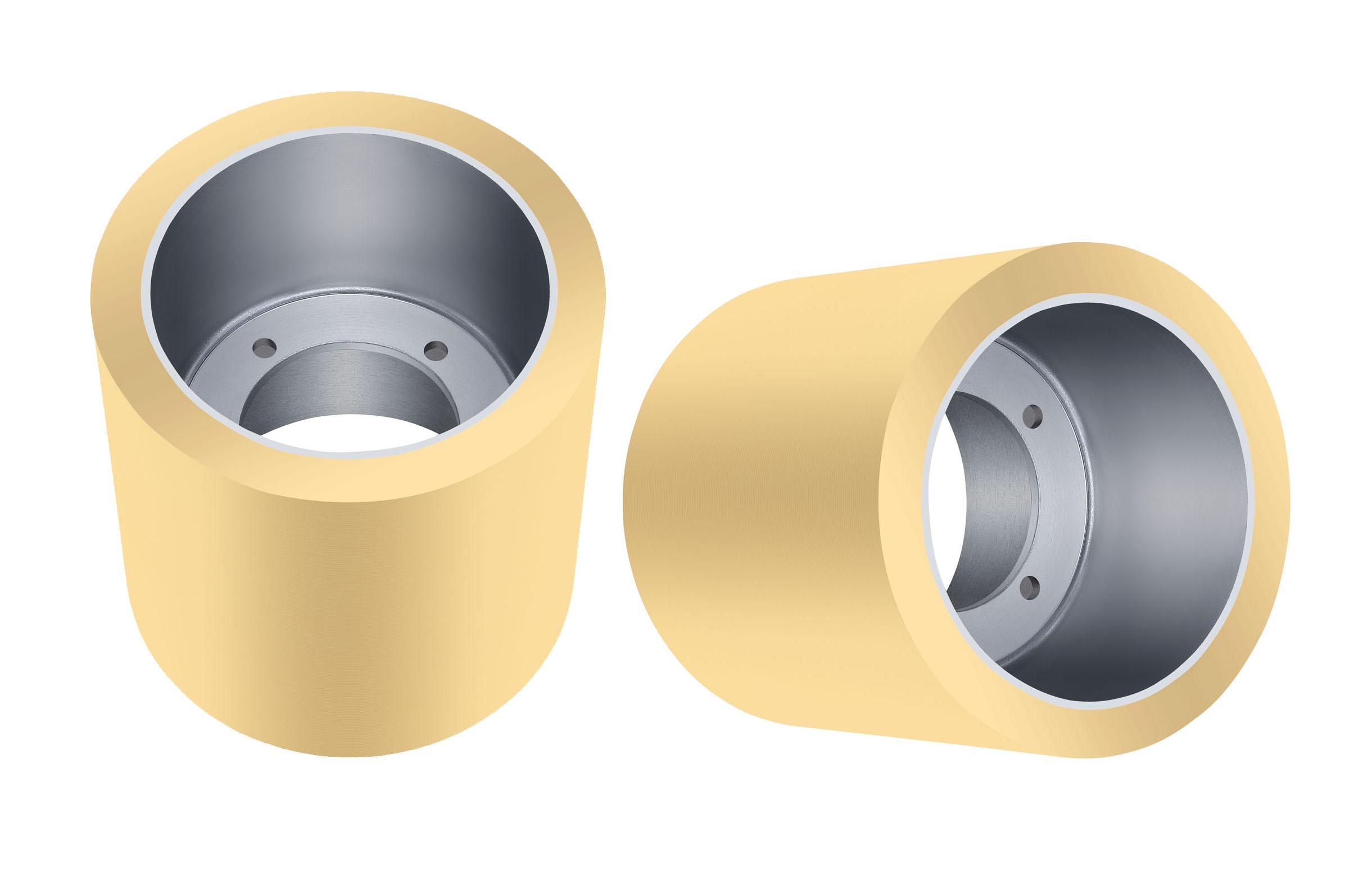

A reliable manufacturer provides polishing wheels that are durable, heat-resistant, and capable of delivering consistent performance over long periods. These wheels are typically made of synthetic rubber, resin, or other high-quality materials that ensure uniform pressure and minimize grain breakage. Premium polishing wheels reduce dust, optimize yield, and maintain the natural aroma and nutritional value of the rice.